THE ENGINE

This remarkable engine was built by Wood Brothers, of Sowerby Bridge, Yorkshire, between 1886 and 1888. It was commissioned on the 12th July 1888. It saw continuous duty from that time to around 1905, when it was relegated to standby duty for storm water pumping.

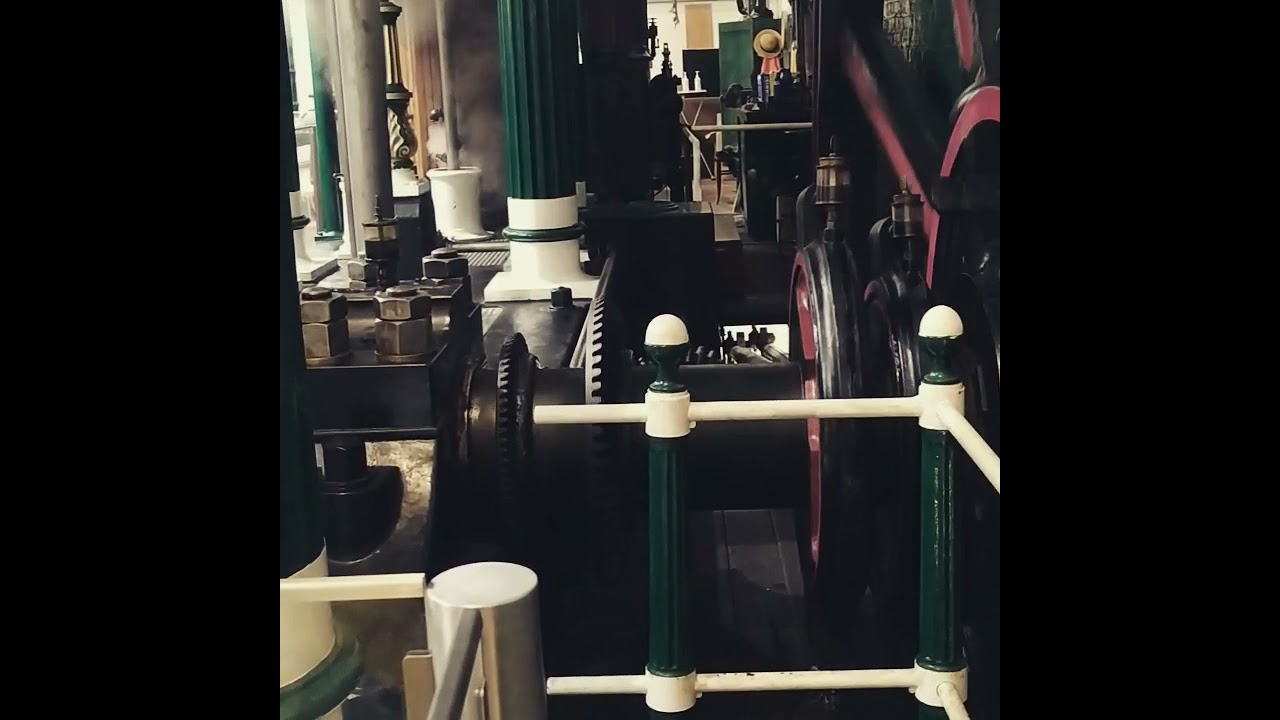

The engine is a rotary beam engine believed to be the last engine produced by Wood Bros., and the only surviving eight column engine in situ. The twin cylinders are capable of being harnessed in serial or compound modes and have an advanced ‘cut-off’ valve gear.

The engine is constructed within its own base and eight column framework to make it independent of the building structure, except at the point where the end of the flywheel axle bearing crankshaft is supported within a cast iron frame, built into the wall of the engine house. The base casting is supported on a solid brickwork structure independent of the walls of the building.

The engine uses the double-expansion compound system, developed by Arthur Woolf around 1804, whereby the steam is first let into a high-pressure cylinder, where it is allowed to expend half its pressure before being let into the low pressure cylinder, to do further work before being condensed. This system allows for minimal fuel consumption.

The engine is rated at one-hundred horsepower and drives two pumps, of the plunger type. Each pump was capable of moving two million gallons-per-day, when the engine was running at sixteen revolutions per minute. The pumps are each twenty-six inches diameter and fifty-one inch stroke.

The eight supporting columns are of the Doric style, in hollow cast-iron, and the general design of decoration to the structure, notably the use of the acanthus leaf motif, follows the "only the best" attitude of the Local Councils and industrial designers of the day.

The flywheel is twenty-seven feet in diameter and weighs approximately seventeen tons. The spokes are of solid cast iron and the rim is of hollow section.

Each cylinder piston rod is joined by a series of interconnected moving rods to the fixed engine framework, forming a parallel motion to the beam. This parallel motion linkage, invented by James Watt in 1784, converts the curvilinear motion of the beam into straight-line motion.

The beam itself stands 17 feet above floor level and is almost 21 feet in length. It pivots on two huge bearings that are lubricated by small oil reservoirs above, as are all the bearings attached to the beam. The flywheel bearings and those driving the valve timing gear shafts are lubricated by the small self-feeding glass reservoirs.

When used to pump sewage, the engine consumed some four hundredweight (200 kilos) of coal per hour. There were two driver/mechanics to operate the engine who lived in two cottages on the site, tied to their employment.